| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Model Number | 16 MM TO 40 MM |

| Brand Name | NCT |

| Material | FOR 500 AND 600 TATA SAIL AND OTHER |

| Click to view more | |

Product Details

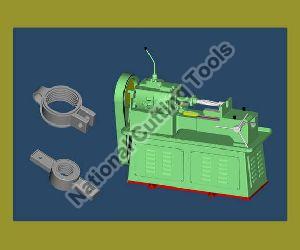

Defining as the most reliable Manufacturer, Exporter and Supplier of superior quality Rebar Coupler, we have carved a niche for ourselves. Rebar Coupler and Rebar Splice are such robust structures which are reinforced in concrete in order to improve its tension bearing capacity. Rebar Coupler that we provide is hailed for high mechanical strength, maximum bonding with concrete, minimum dimensions, simple assembly and highest order of safety. Rebar Coupler is widely applied in the process of piling, micro-piling, slip-forming, framework protection, slope protection, etc.

Cutting : The end of the reinforcement bars is sawn square.

Cold Forging : With the help of cold forging, the sawn end of the reinforcing bar is then enlarged. With this the core diameter of the bar is increased to pre-determined diameter.

Threading : An ISO standard metric thread is then cut.

Specialties Of Our Rebar Couplers

- Technically Perfect :

Concrete structures need to be reinforced to improve their load bearing capacity and our Rebar Couplers are perfectly designed for that. Our Rebar Couplers impart unmatched mechanical strength to the RCC structures thus ensuring complete safety even in the rugged conditions of seismic activity. The continuity of our Rebar Couplers allows for grounding electrical current. - Flawless Design :

Rebar Couplers, offered by us, are exemplary for their flawless design that allows better concrete flow and consolidation while at the same time reducing rebar congestion. Such designing minimizes reinforcement fixing errors and offers greater flexibility in structuring RCC. - Simple Installation :

Simple mechanical ways are adopted for installation of Rebar Couplers. The simplicity of the installation process saves significant amount of time and labor. The benefits are immediately reflected in the reduced costs of the construction project. - Installation Of Rebar Couplers :

- Good quality shear cut bars with sharp perpendicular cutting or saw cutting may be used. The threading is provided on bar ends with proprietary branded threading equipment and thread cutting tools.

- Threading of reinforcement bars must be carried out as per NCT RE-BAR COUPLERS by trained operator. The thread checking gauge is used for checking the threads. The threads shall be covered by thread protection plastic cap while storing.

- The bent bars may be threaded on threading machine provided straight length of the bent bar-end to be threaded is more than 0.5 m. If not so, the bars may be threaded in straight lengths, connected thoroughly and bar bending is carried out subsequently. The bent must be minimum 100mm apart from thread bar end.

- The bar is connected to coupler sleeve initially by hand tightening and then with pipe wrench.

- The NCT RE- BAR Couplers full strength threaded butt joining that achieves strength with fully engaged threading of coupler and reinforcement bars. Therefore, it is essential to ensure adequate tightening of joining connection for effective load transfer.